Construction method, materials and approaches

Historical origin: The aluminum sandwich chassis

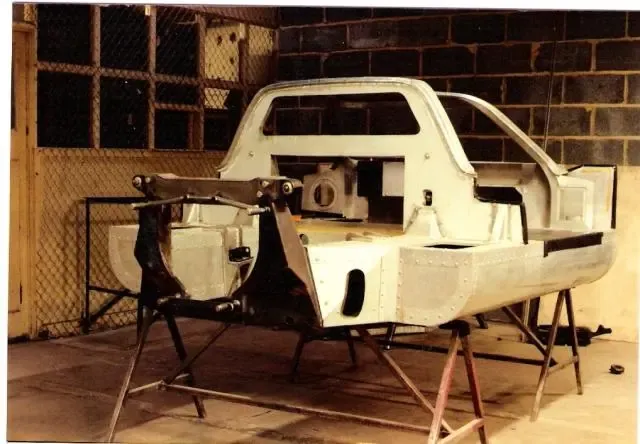

The Ford GT40 MKIV was the first racing car to use an innovative aluminum sandwich chassis. This construction, consisting of straight panels, set standards for lightweight construction and stability at the time. Nevertheless, I quickly realized that it would be almost impossible to implement this design myself in such a way that all strength requirements would be met.

A look into the past: initial sketches as a basis

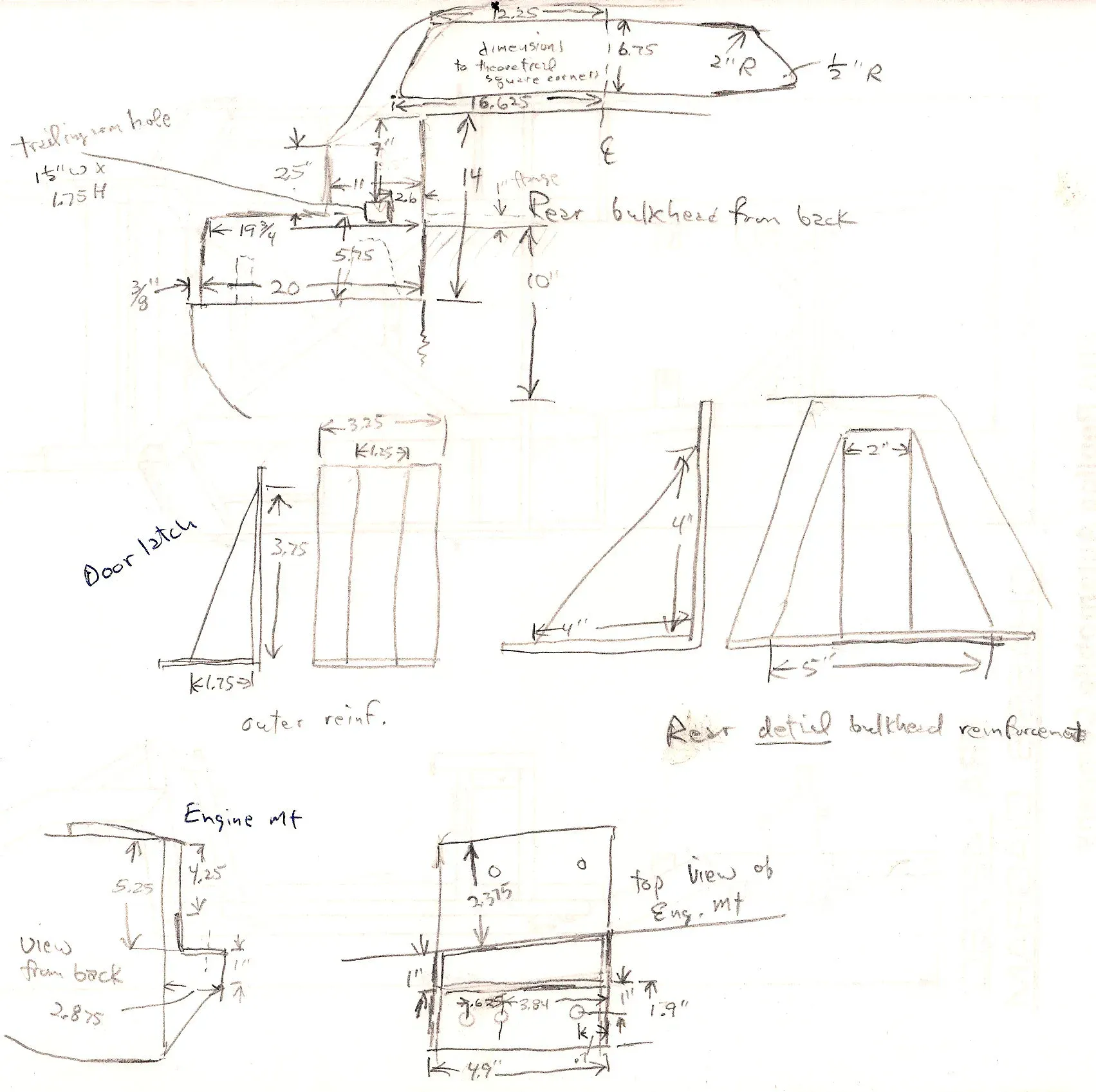

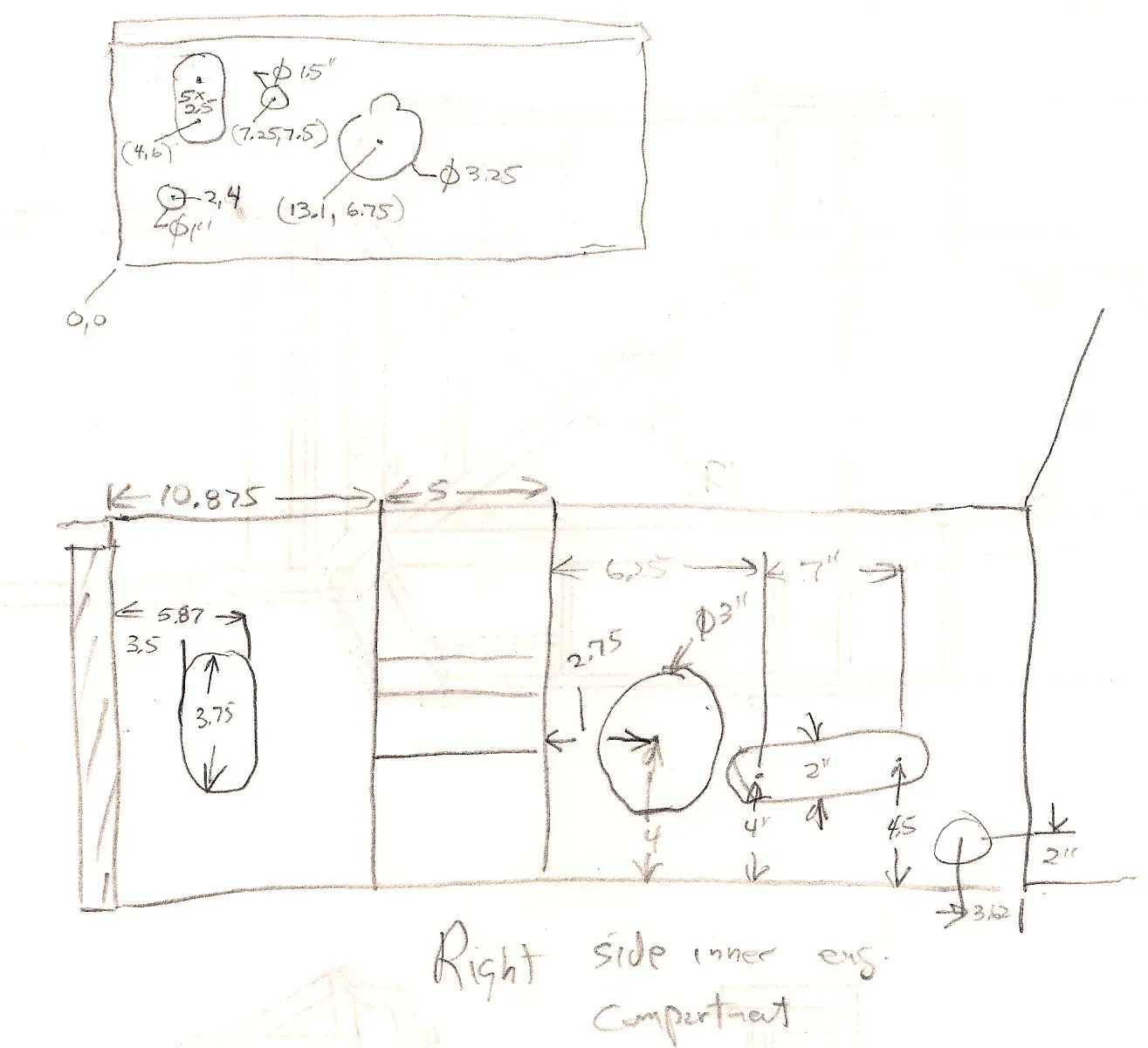

This is where my many years of membership of the GT40s.com forum came in handy. An acquaintance from the community, Bob Putnam, had once restored an original GT40 MKIV and created about twelve pages of simple hand sketches with the most important dimensions. He generously made these documents available to me – a milestone for my project, for which I am very grateful to him.

From paper to digital: CAD reconstruction

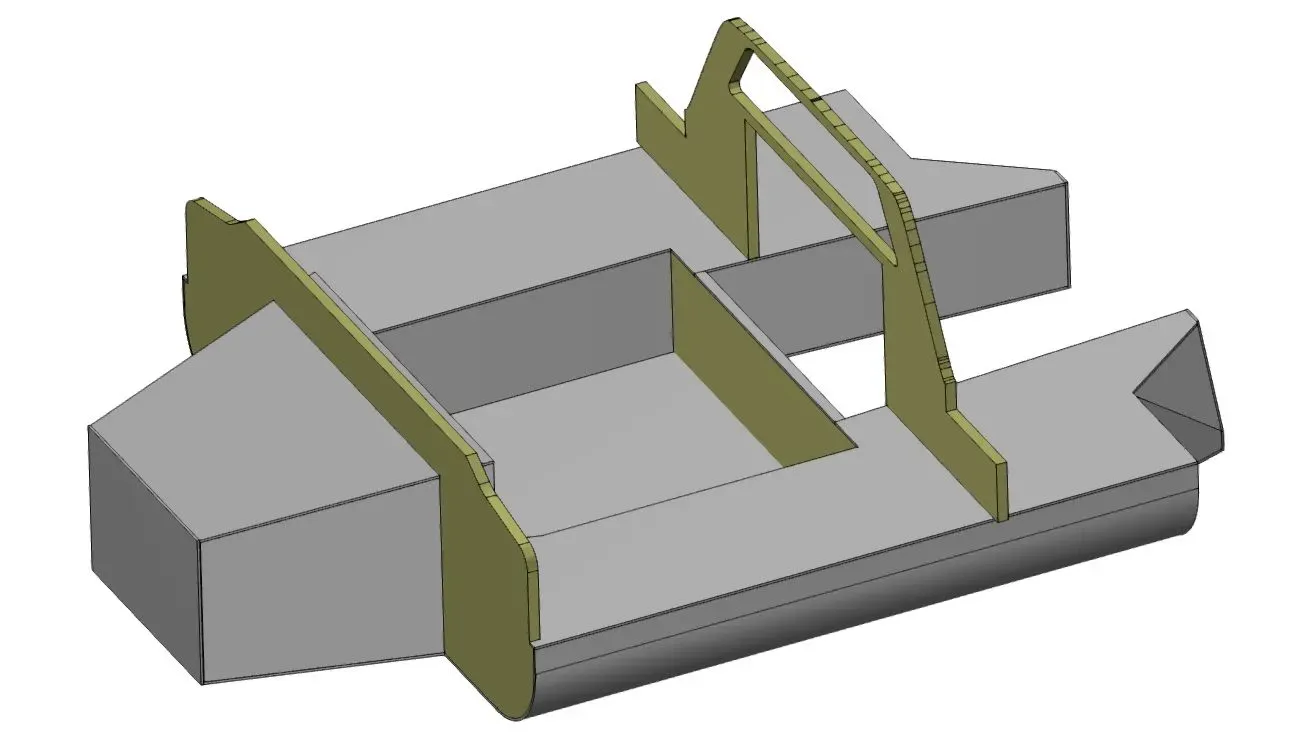

However, the sketches were anything but easy to decipher. (See below) I spent many hours interpreting the dimensions, converting them and transferring them to my CAD program. But the effort was worth it: piece by piece, the chassis took shape in digital form and allowed me to take a closer look at the design.

The perfect addition: original plans from Sweden

The biggest surprise came later when my friend Göran from Sweden sent me original plans of the chassis from the Ford racing department. These plans enabled me to check all the dimensions again and refine my CAD design. It was a fascinating moment to be able to understand the technology and precision of the engineers of the time at close quarters.

The modern approach: a tubular lattice frame as the basis

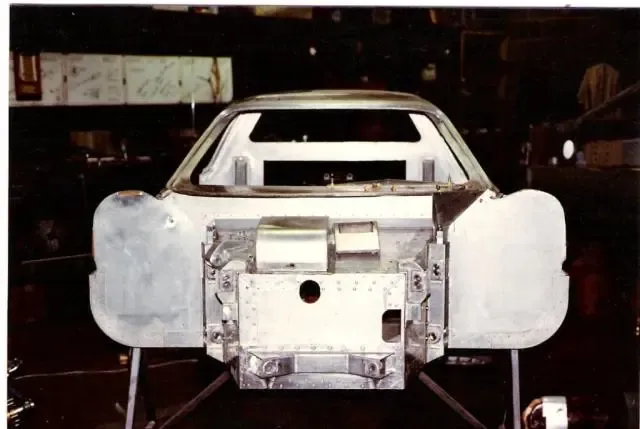

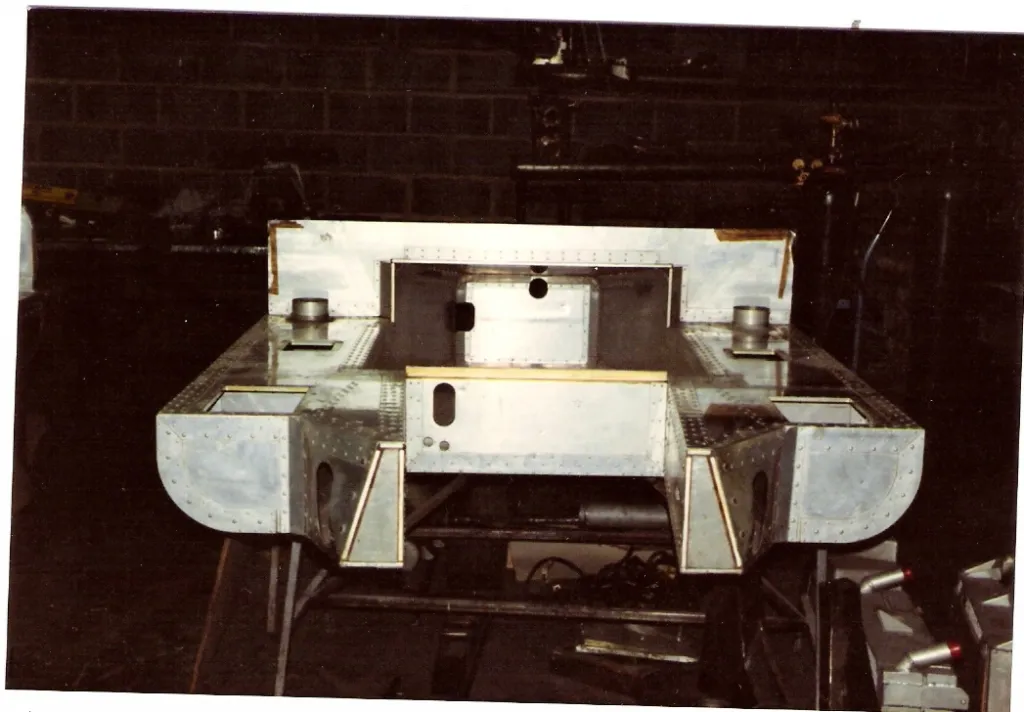

As early as 2018, it became clear to me that an aluminum sandwich chassis like the original was not feasible with my possibilities. Instead, I opted for a tubular trellis frame, which I planned in such a way that its external dimensions were within the original chassis. This decision allowed me to create a solid base that was both stable and technically feasible.

Optical illusion: The cladding with aluminum sheets

To achieve the visual impression of the aluminum honeycomb sandwich chassis, I planned to cover the tubular lattice frame on both sides with thin aluminum sheets. The resulting inward width deviation of around 15 mm due to the tube diameters was hardly noticeable and is practically invisible to the untrained eye. This makes it possible to create an authentic look, which visually mimics the original.

Detail work: rivets and angle strips

To further enhance the impression, I decided to install hundreds of rivets and numerous angle strips. Although these steps were time-consuming, they gave the frame the finishing touches and brought it even closer to the historical model.

Leave a Reply

You must be logged in to post a comment.