The rims

Rims – buy or make them yourself?

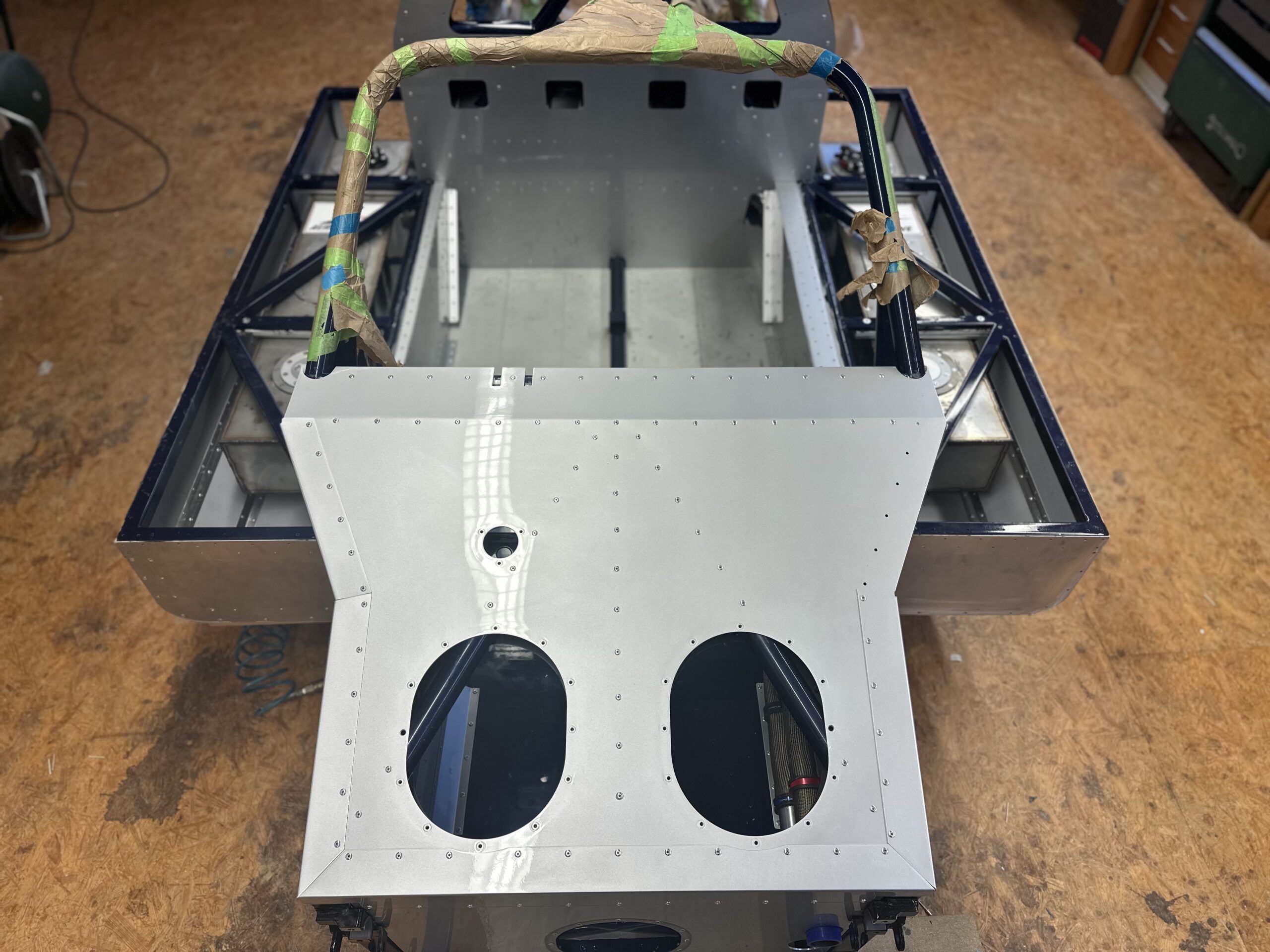

Rims are one of the most striking features of the GT40 MIKV. During the construction of the chassis, I also experimented with more modern 17” rims. These would have provided more space for the suspension and brakes. But in the end it just didn’t look good, as it made the proportions of the whole car look inharmonious and the classic look of the GT40 was lost. That’s why I stuck with the original dimensions – 8.5×15“ at the front and 12×15” at the rear. Even though this presented some additional challenges, it was only a small step to the decision to adopt the original design as far as possible.

1. Buy or make yourself?

Currently, I only know of one manufacturer from which you could possibly buy such rims: RaceCar Replica (RCR) from the USA. My acquaintance Morton Larsen from England owns a set and was kind enough to send me numerous pictures of it. Unfortunately, I was not convinced by the quality. The milling marks are clearly visible, which would require extensive reworking such as grinding, polishing and coating to achieve an appealing appearance and the desired surface quality. In addition, these rims are tied to the RCR mounting system – not an option for me. The price including import to Germany is also not insignificant, and my previous experiences with RCR were not particularly good.

However, Morton not only sent me pictures, but also detailed measurements. That was the deciding factor: a new design was needed.

2. rim design

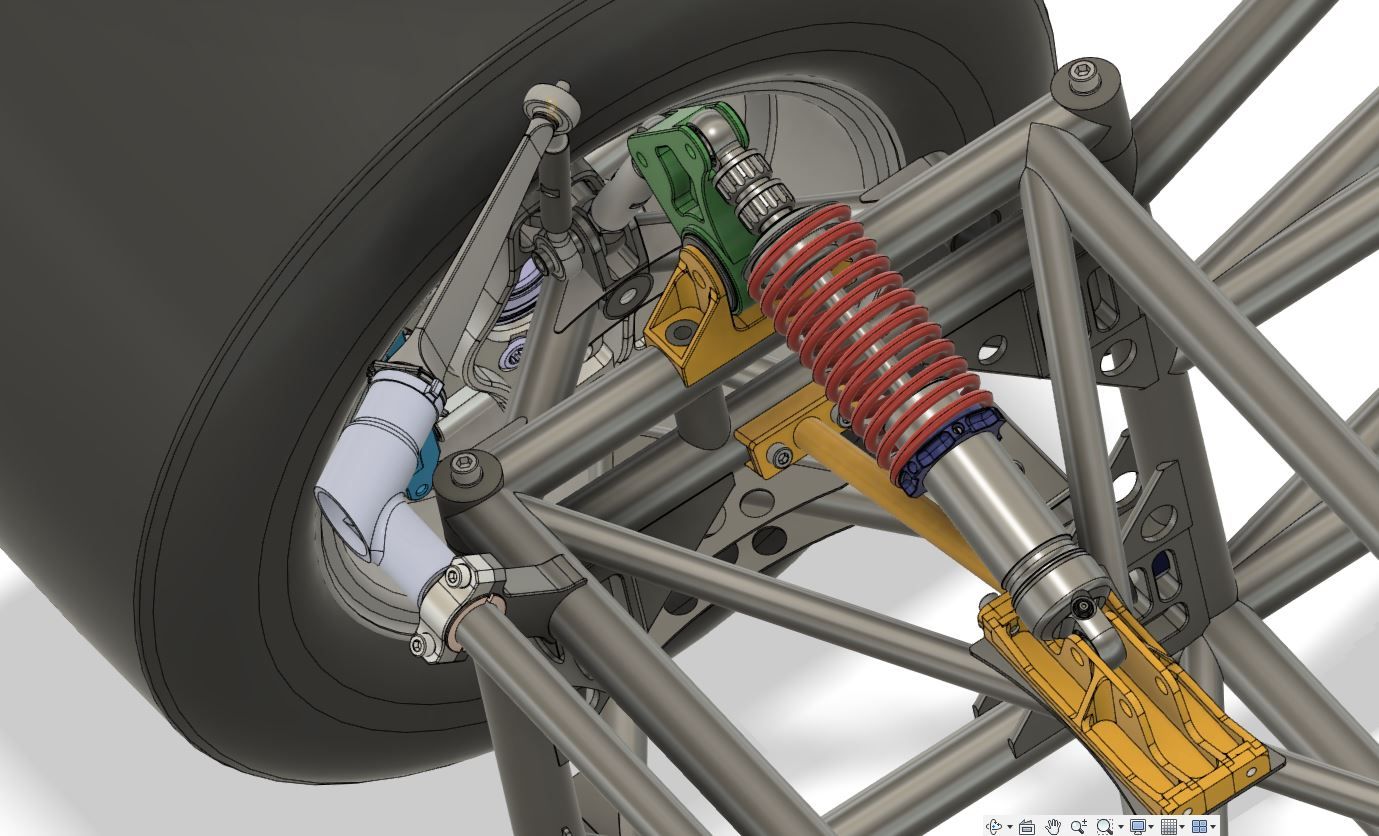

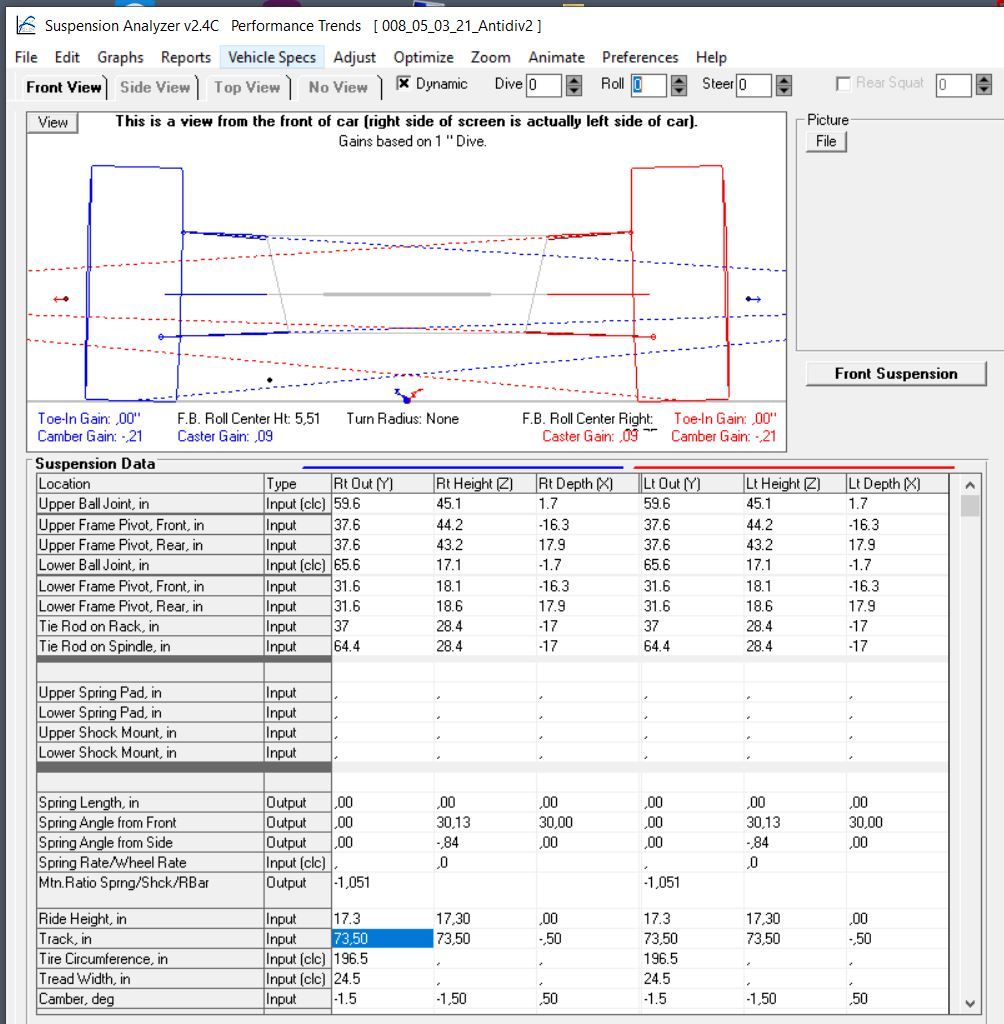

Designing wheel rims is a complex task. It’s not just about the design, but also about numerous technical details: What should the wheel mounting look like? What strength is needed? A wheel offset to match the kinematics of the chassis. How should the tire contact surface (hump) be designed? And much more.

At first, I wanted to make it easy for myself and build a three-part rim. The distinctive center with the fan blades was to be CNC-milled, while the front and rear rim halves would be bolted together. But after I had designed it that way, I realized that the visible screws didn’t look good. So I decided on a two-part construction with the screws hidden on the inside. However, this increased the milling effort considerably, especially for the deep wheel arches on the rear axle.

I was able to obtain the required multi-part wheel rims from a supplier of BBS wheel rims. But on closer inspection, the quality was disappointing – in particular, the contour of the tire contact surface with the hump did not meet DIN standards or my expectations. So I finally decided on a monoblock rim that was milled out of a single piece of metal.

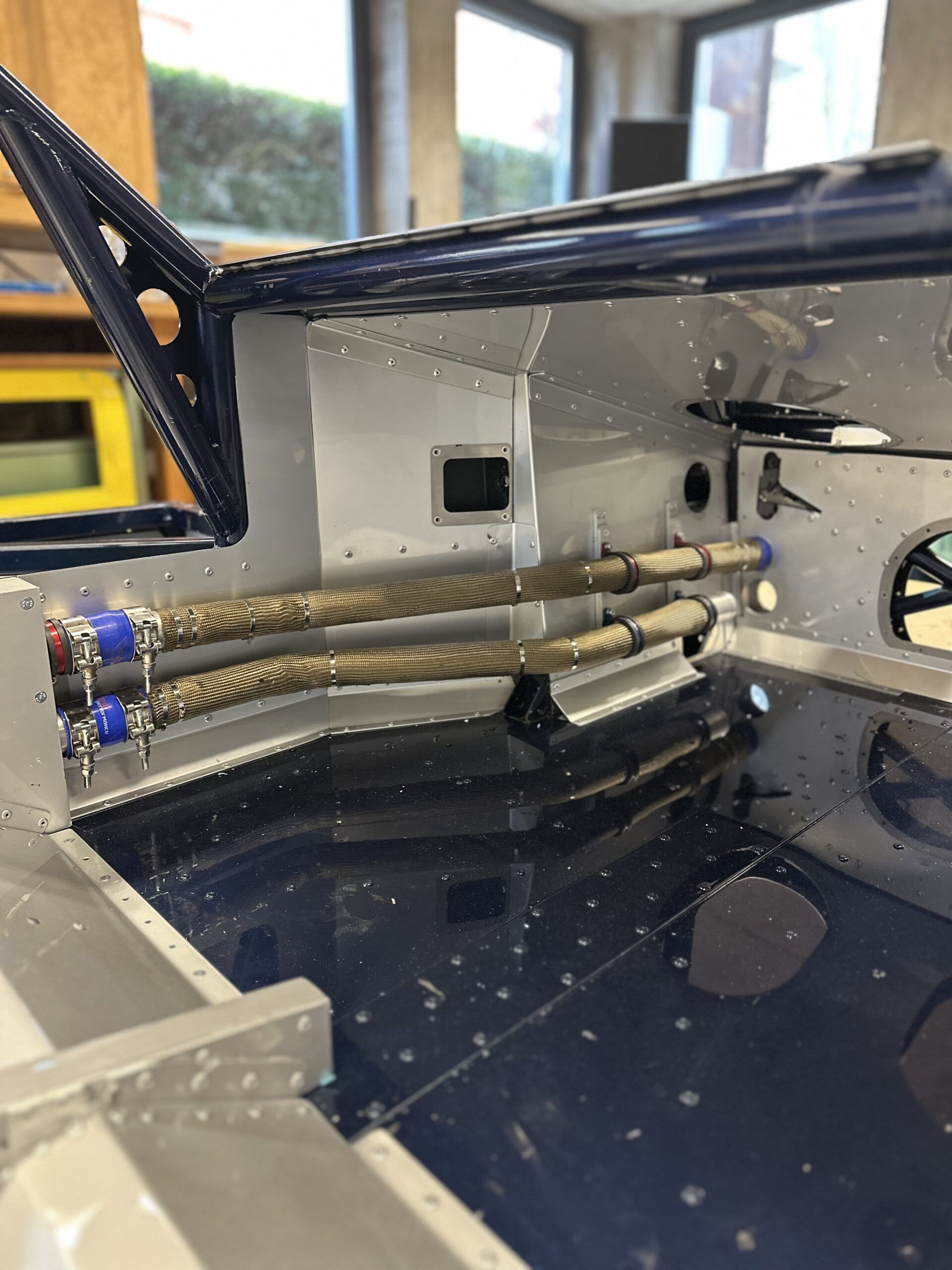

In doing so, I also had to deal intensively with the central locking system. At first, I thought of the usual adapter plate solutions until I came across the manufacturer “ZETA” from Swabia. This company offers ready-made central locking hubs that are also used in GT3 racing by Porsche and other manufacturers. I will write a separate post about this.

Ultimately, I revised the rim again – for the umpteenth time. The result may not be the lightest, but in terms of quality and durability, it absolutely meets today’s racing standards.

3. contract manufacturing

Once the design was finalized, I had to find a suitable manufacturer – a company that could take over the entire process from quality assurance and strength calculations to production and coating. And all this had to be as affordable as possible and for just a single set!

From my network, I kept hearing about the high costs of design studies in this area – even for rims that are supposed to be visually convincing but don’t have to meet any technical requirements. But through my contacts in racing, a small company in Spain that manufactures small series for Formula 1 and numerous motorsport teams was recommended to me: Goyarfw.

This high-tech company near Valencia impressed me from the outset with its expertise and helpfulness. After analyzing my CAD data, they found a few modifications I needed to make. For example, the turbine blades in the wheel center had to be opened about 15° further to ensure that there was still enough space for the milling head on the deep rear wheel rims. The revised design was then subjected to an extensive strength analysis to ensure the required safety.

In addition to the pure quality, the manufacturing accuracy also gave me a headache. My bobbins – the five cams of the rim on the inside – should be manufactured with a tolerance of only 3/100 mm. Both the hub manufacturer and the rim manufacturer had to guarantee this, otherwise the five round cams would not fit exactly into the intended holes. It was not just about the diameter, but also about the bolt circle and the exact distribution.

Why such a narrow tolerance? In racing, 1–2/10 mm is usually the norm here to enable a quick wheel change. However, this larger tolerance quickly leads to so-called “micromovement”: when accelerating – especially with an engine with over 730 Nm of torque – the round hole gradually becomes oval due to the constant loads. In racing, these rims are replaced after a season, but for me that was out of the question. Since I don’t have to perform quick pit stops, precision was more important to me than quick assembly.

In the end, my concerns proved to be unfounded. The rims and hubs were manufactured with such high precision that everything fit perfectly. As additional proof of quality, I received a comprehensive measurement protocol with the delivery, which showed compliance with all specifications.

Conclusion

I could go on writing many more details about the challenges of designing and manufacturing wheels. But it should be clear even so that it is no easy undertaking. You need a lot of knowledge – or you know the right people to ask.

If any of you are also thinking about making your own rims, feel free to contact me. Goyarfw and I have now entered into a small partnership. This means that I can not only facilitate the construction, but also the production.