The role of software and technology in planning

Everything revolves around CAD

CAD software played a central role in my project right from the start. Without modern tools and technologies, it would simply have been impossible to realize such a complex project as the development of a complete racing car.

Getting started with TurboCAD

I started my work with TurboCAD, which was obvious: For over 20 years I have been running the TurboCAD Training Center and have been responsible for training courses in Germany, Austria and Switzerland. During this time, I have conducted hundreds of training courses and taught numerous customers how to design in 2D and 3D with TurboCAD.

I used this familiar software to create the first designs for the tubular frame and began with the kinematic design of the chassis in 2D. TurboCAD was ideal for this basic work – fast and efficient.

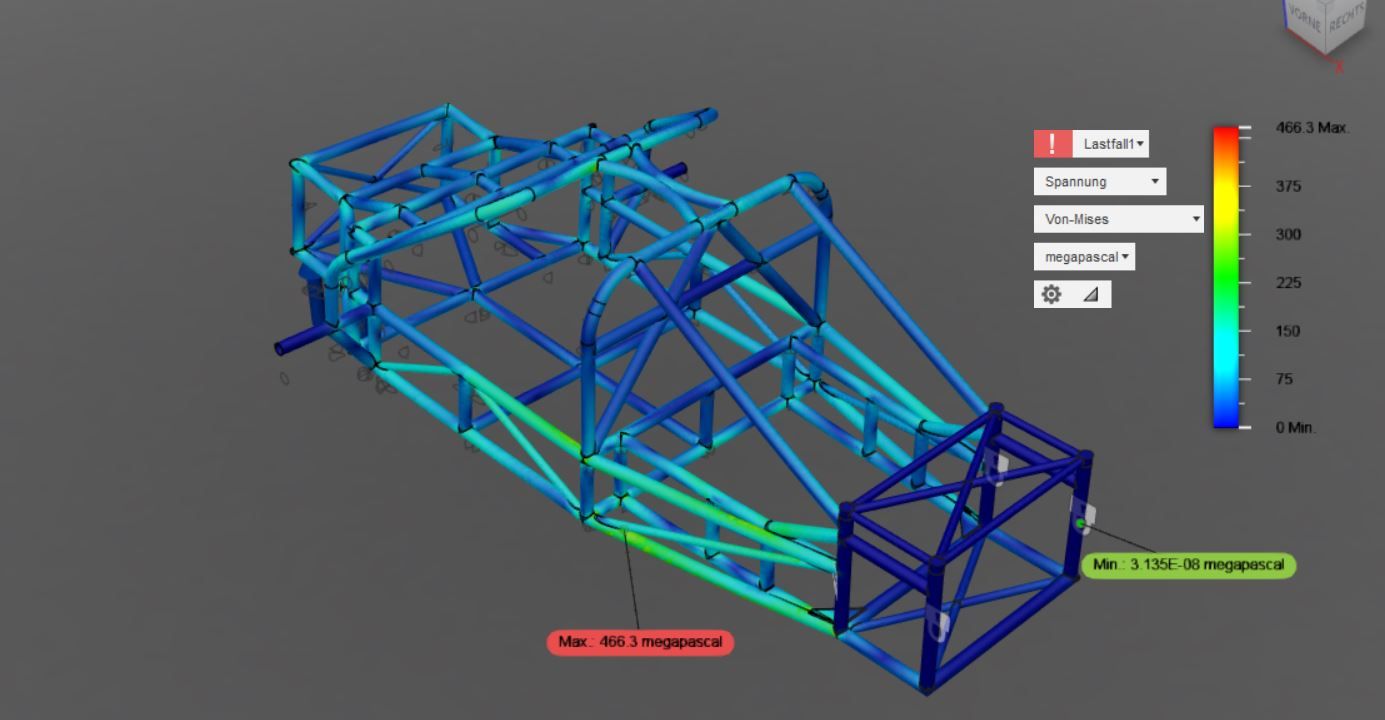

But I soon reached the limits of the program: TurboCAD ‘s functions were not sufficient for the next steps, especially the strength analysis of the frame.

The switch to Fusion 360

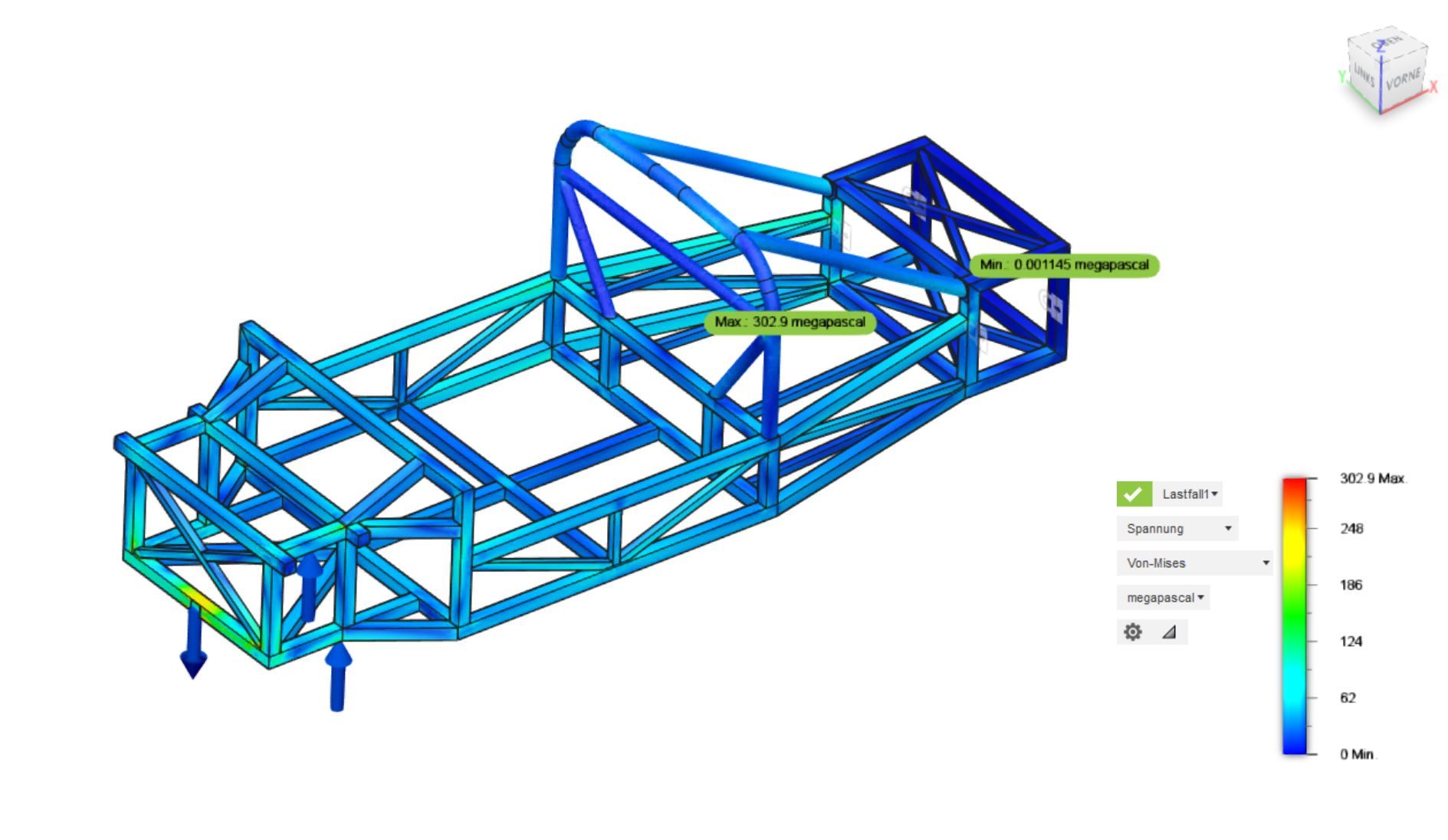

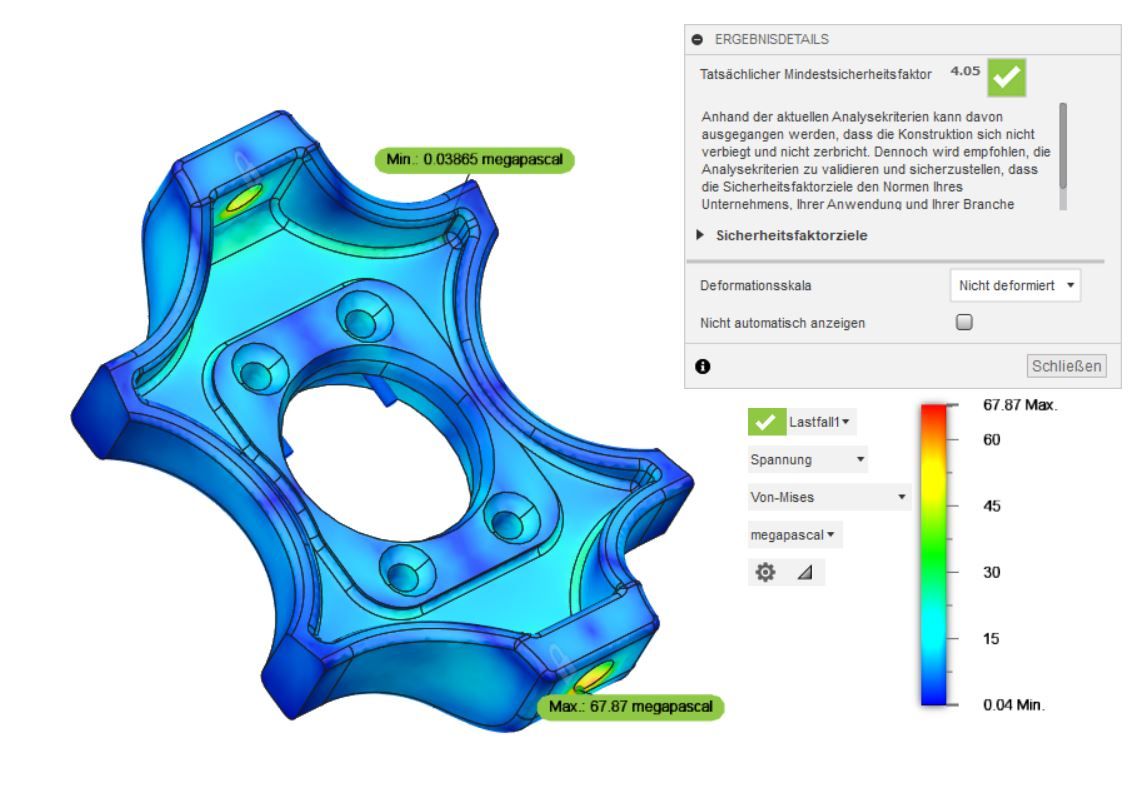

It was clear that I needed more powerful CAD software, so I decided to use Fusion 360. Although I have been working with CAD since 1998, this switch was a challenge. The software not only offered significantly more functions, but also a completely different approach to design. Especially the simulation was new to me and required intensive training.

Despite the extra effort, the change was worth it. Fusion 360 enabled me to perform strength analyses and more detailed modeling, as well as handling very large volumes of data, which was crucial for further planning.

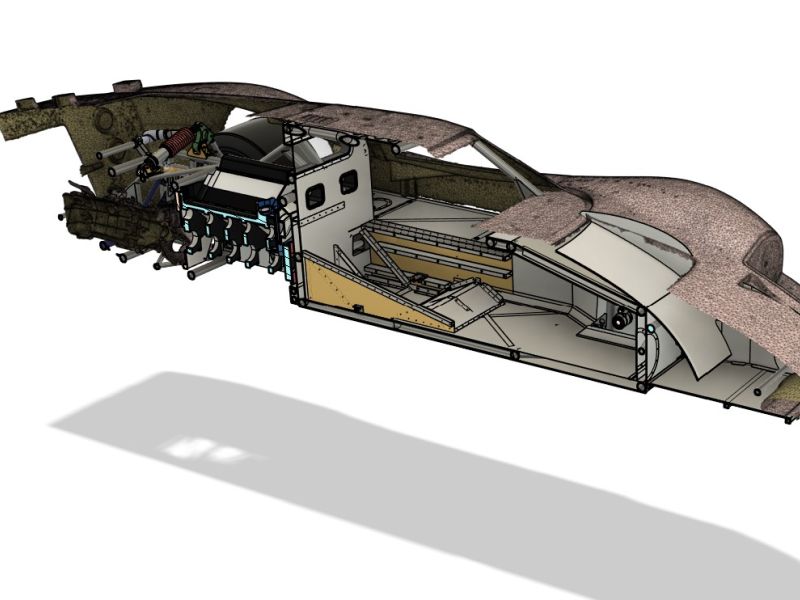

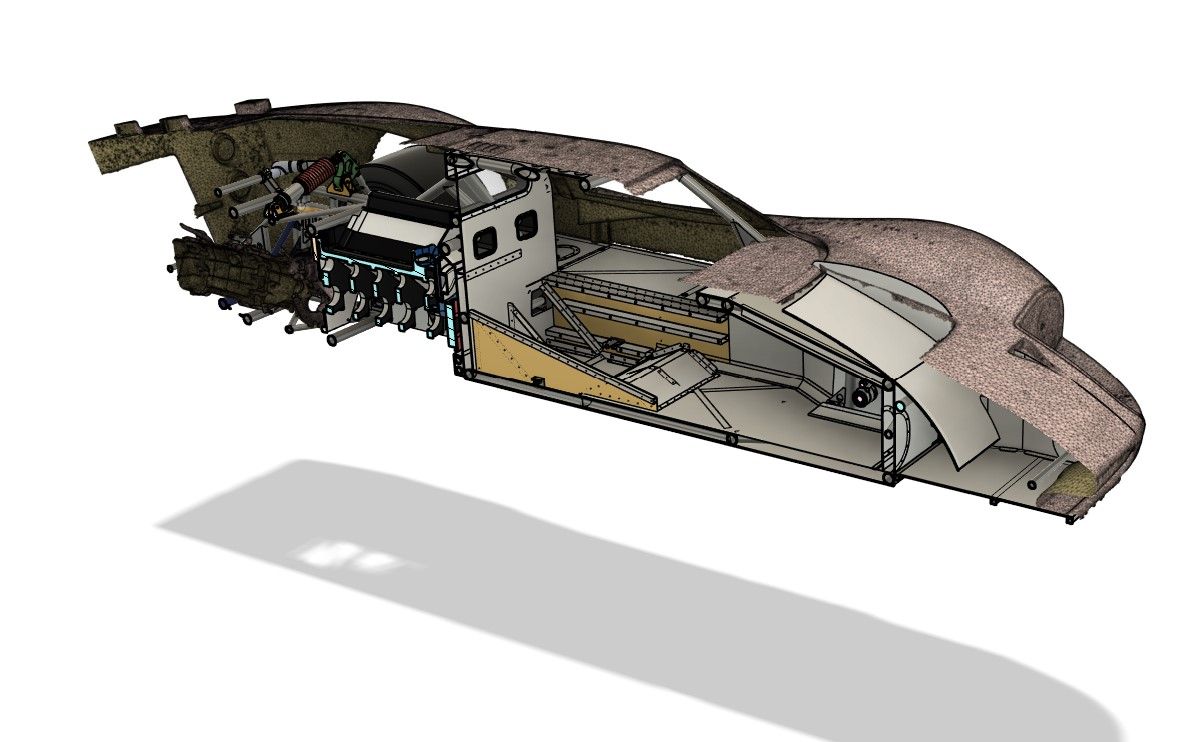

Working with 3D scans

Another important part of my planning was working with 3D scans. I captured components such as the bodywork and the gearbox using an Artec EVA 3D scanner and the associated software. I used this data as a reference in my CAD model to ensure that the frame would fit under the GRP body.

I would especially like to thank my friends from MotoPark who not only supported me with the necessary hardware, but also helped with the preparation of the data. Without their help, this part of the work would have been much more difficult.

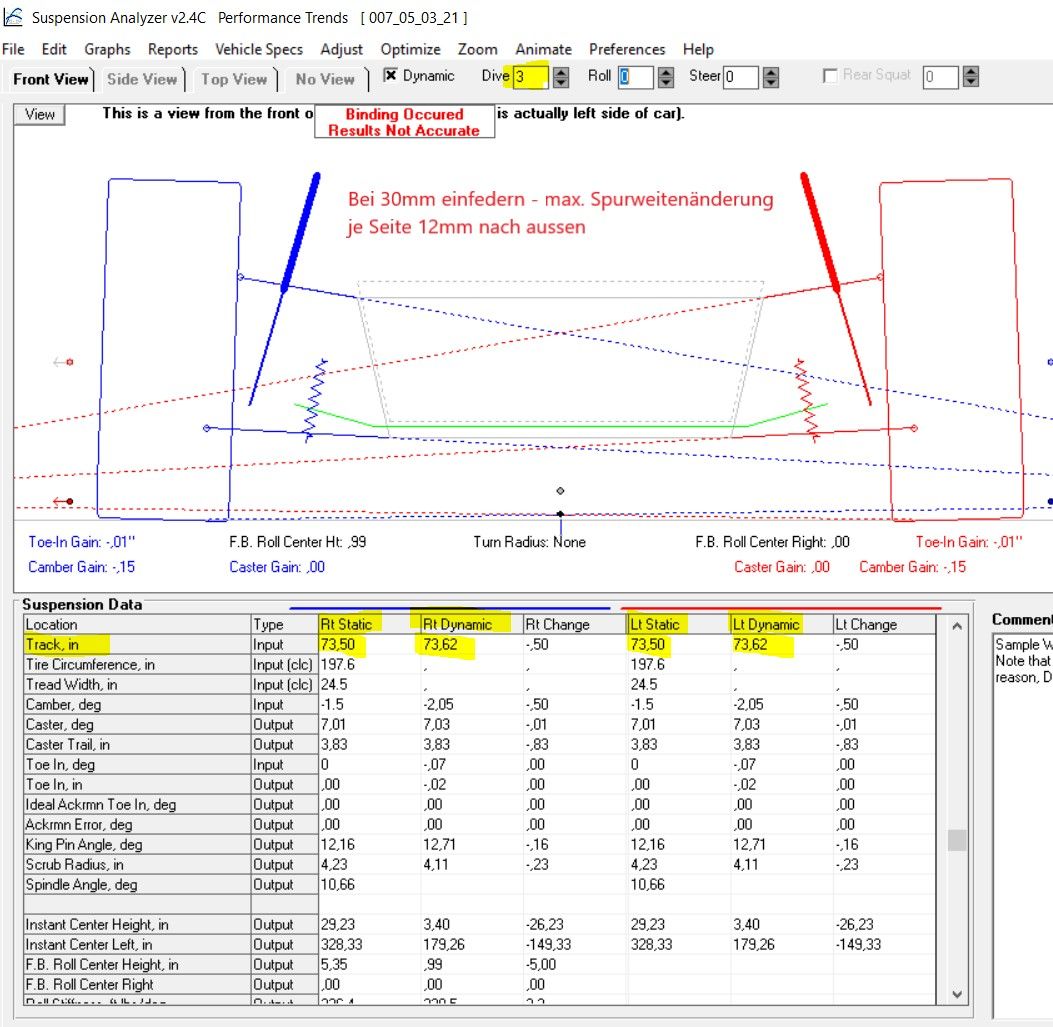

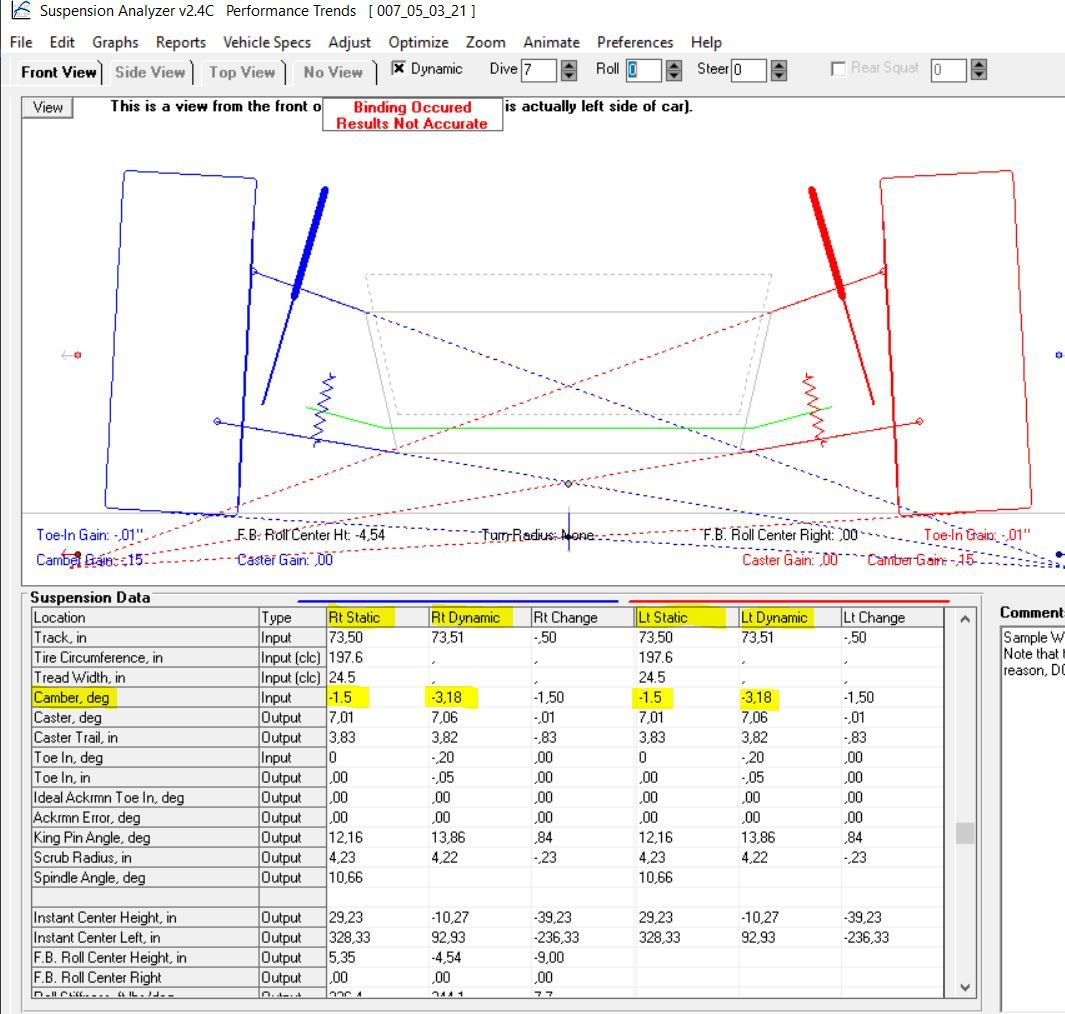

Chassis development with specialized software

For the development of the suspension I used the Suspension Analyzer from the company Performance Trends, Inc. from the USA. I also experimented with the online tool Suspension Geometry Calculator from racing_aspirations. Both programs offer different advantages and disadvantages and are among the few affordable options for private individuals – in contrast to the professional solutions, which can quickly cost tens of thousands of euros.

Conclusion

The use of software was essential during this phase of my project. Between 2019 and May 2021, I worked exclusively on design and planning – an intensive period in which countless hours were spent on development. Only then did the actual construction begin, with phases of design, the production of components and the actual assembly alternating again and again to this day. This iterative process requires patience, precision and, above all, a great deal of passion for every detail. But it is precisely this variety that makes this project so fascinating for me.

Leave a Reply

You must be logged in to post a comment.